Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Tel.: +86 13358378970

E-mail: sales6@saulplc.com

May. 10, 2023

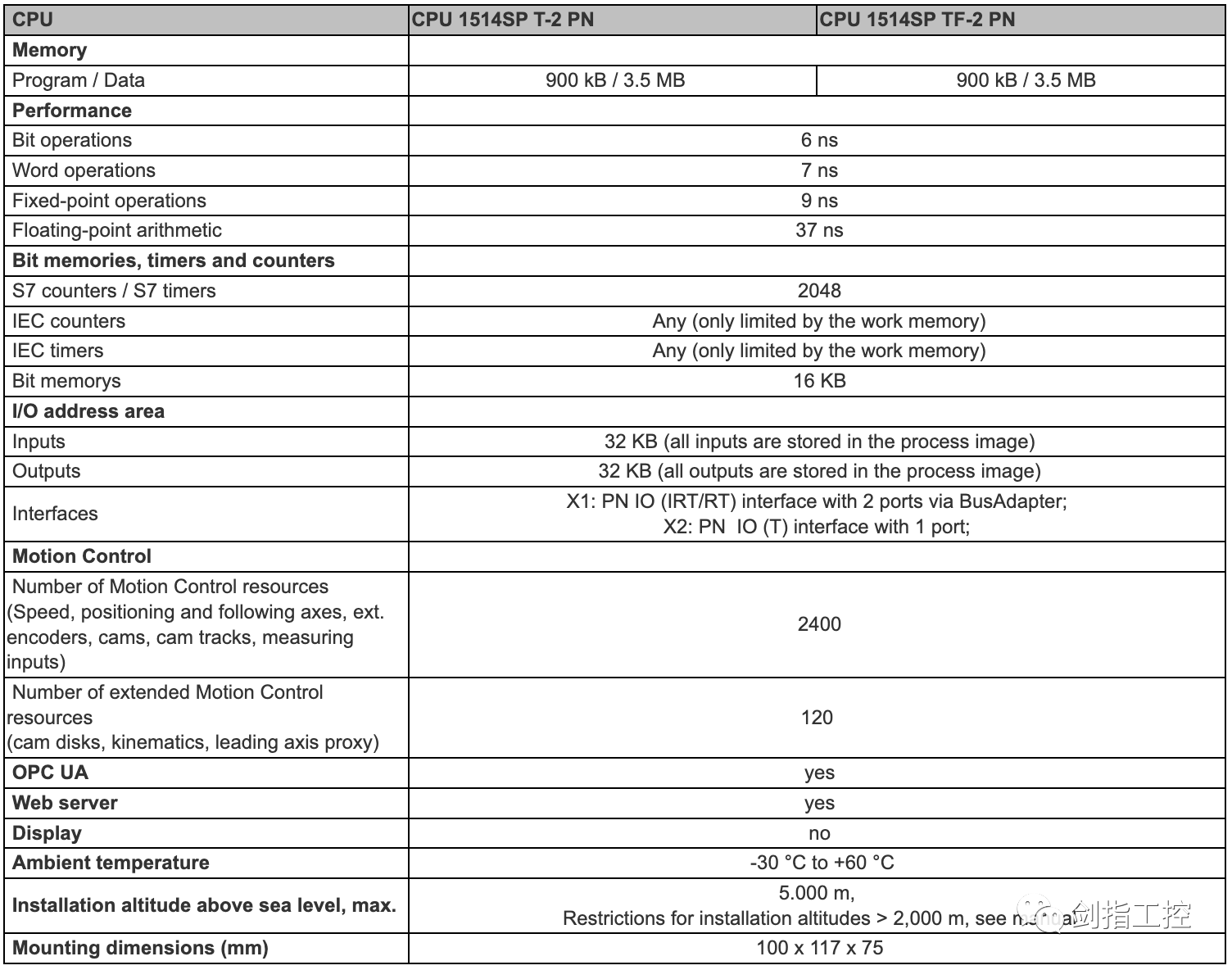

Recently, two new CPU extensions have been added to the SIMATIC ET 200SP distributed I/O system - CPU 1514SP T-2 PN and CPU 1514TP TF-2 PN. They not only have extended motion control functions, but also are based on the innovative firmware version V3.0 of the SIMATIC S7-1500 controller. Currently, two CPUs have been released and can be delivered. CPU 1514SP T-2 PN and CPU 1514TP TF-2PN are suitable for applications with moderate requirements for program range and processing speed. It can solve demanding applications with a focus on motion control, such as cross industry automation tasks in serial connection, special machines, and factory engineering. In addition, these CPUs are also suitable for distributed configuration applications through PROFINET IO.

TF-2 PN

T-2 PN

Equipped with 2 integrated interfaces:

Three PROFINET interfaces: X1 with 2-port switch (suitable bus adapter required)

——PROFINET IO RT and IRT

——X2 with 1 port - PROFINET IO RT

Highlights of CPU 1514SP T/TF-2 PN:

Integrated motion control function for controlling speed control, positioning, and synchronizing shafts (gears and cams, speed gears), supporting external encoders, output cam/cam tracks, and measurement inputs

Technical objects used to control the kinematics of up to four interpolated axes, such as Cartesian portals, triangular pickups, roller pickups, articulated arms, cylindrical robots, tripod pickups, and SCARA

Cross PLC synchronization operation for synchronizing multiple SIMATIC S7-1500T controllers

Motion control performance (approximately 11 positioning axes at a 4ms servo clock, achieving a 35% system utilization rate through motion control)

Security integration

Innovative design and handling

Integrated System Diagnosis

Highlights of Failsafe CPU 1514SP TF-2 PN:

Distributed configuration through PROFINET IO and PROFIsafe

All common safety function libraries certified by the German Technical Supervision Agency (T Å V)

Support validation through compliant program documentation

Easy reusability through library concepts

Can be used for safety related tasks that comply with IEC 61508 to SIL 3 and ISO 13849-1 to PL e

Number of motion control resources occupied by process objects:

Speed axis=40

Positioning axis=80

Synchronous axis=160

External encoder=80

Cam=20

Cam trajectory=160

Probe=40

The number of motion control resources occupied by the cam disc object:

Cam disc (1000 points and 50 segments)=2

Cam disc (10000 points and 50 segments)=20

Moving object=30

Front Guide Axis Proxy=3

Basic parameters:

Navigation

Add.: 9D, 9th Floor, Huguang Building, Hubin West Road, Siming District, Xiamen City, Fujian Province, China

Tel.: +86 13358378970

Mob.: +86 13358378970

E-mail: sales6@saulplc.com

WhatsApp: +86 13358378970

Wechat: +86 13358378970